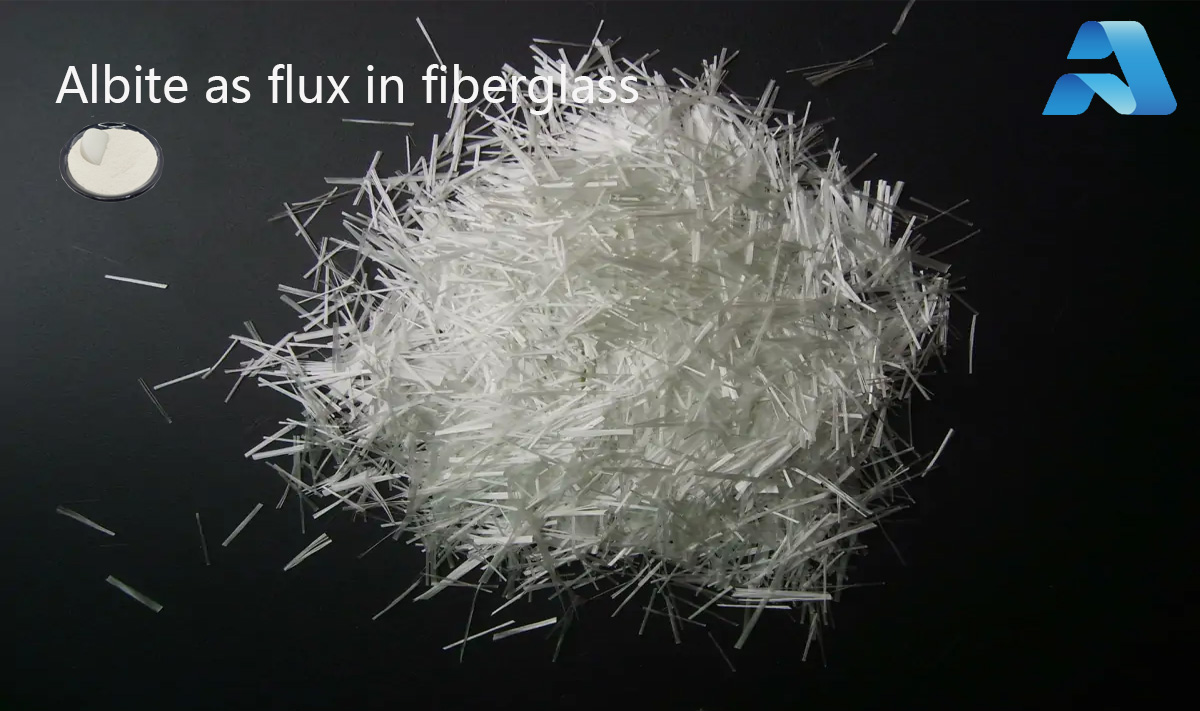

The application of albite as flux in glass fiber production has shown unique value and potential. Albite, a sodium-rich, aluminum-rich silicate mineral whose main components are sodium oxide, aluminum oxide and silicon dioxide, plays a vital role in the glass fiber industry.

- In the production process of glass fiber, the melting temperature of the melt is a key factor. The high content of sodium oxide in albite acts as an effective flux, which can significantly reduce the melting point of the glass melt, thereby reducing energy consumption. This feature is particularly critical in the production of microelectronic glass fibers, as it not only shortens the melting time and reduces production costs, but also helps reduce greenhouse gas emissions and achieve green production. Additionally, due to the lower melting point, the life of the kiln can be extended, further improving overall production efficiency and sustainability.

- In addition to lowering the melting temperature, the alumina and silica components of albite react with the glass matrix during the melting process to form a stronger network structure. This structural reinforcement is particularly important for glass fiber because it is directly related to the stability and reliability of the product in extreme environments. By enhancing the mechanical strength of glass fiber, albite enables the product to withstand greater external forces, thereby increasing the product’s service life and safety. At the same time, these ingredients can also improve the chemical resistance of glass fiber, enabling it to maintain stable performance in various harsh environments.

- In glass fiber production, melt viscosity control is also crucial. The addition of albite can finely adjust the fluidity of the melt, ensuring uniform fiber distribution and continuous production. This not only improves the appearance quality of the product, but also ensures the uniformity of the internal structure of the fiber, thereby improving the overall performance of the product. In addition, the introduction of albite powder can also significantly improve the optical properties of glass fiber. By adjusting the ratio of albite, the refractive index, transmittance and dispersion characteristics of glass can be optimized, making microelectronic glass fiber more suitable for photoelectric transmission, Fields such as optical device manufacturing show broader application potential.

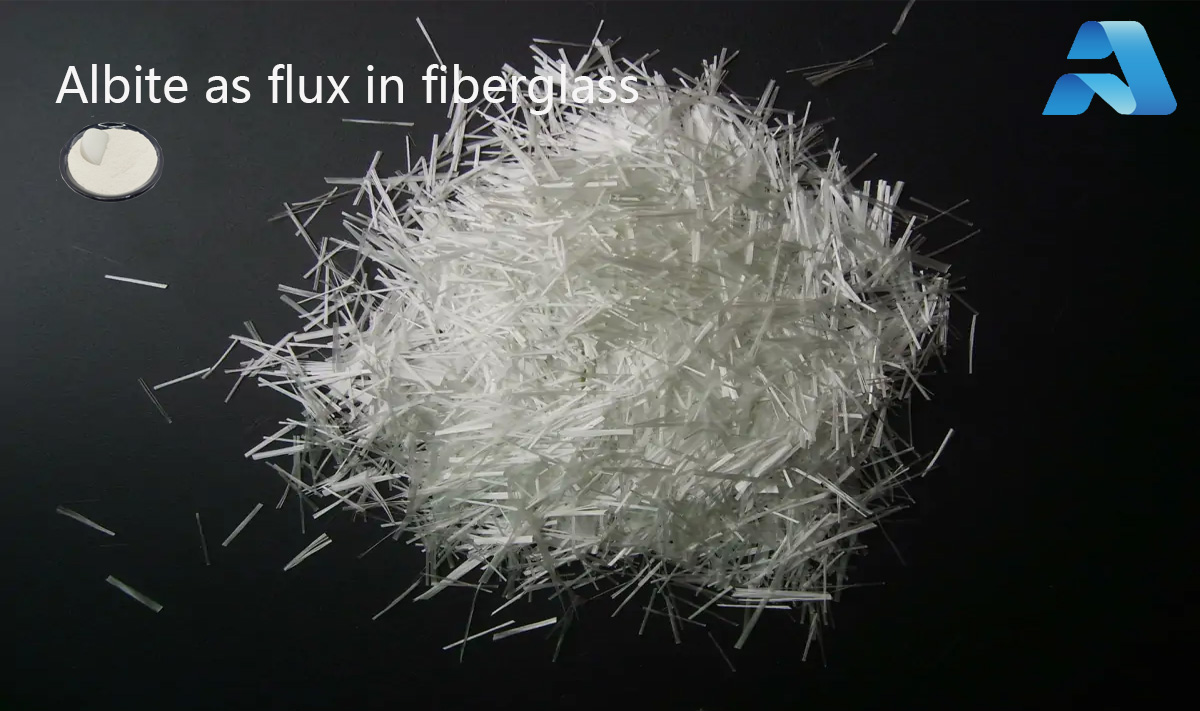

Application Advantages:

- First, albite can effectively lower the melting temperature of glass melt, which is crucial in the production process. The reduction in melting temperature means a significant reduction in energy consumption, which is not only reflected in the reduction of electricity consumption in the smelting stage, but also in the reduction of energy consumption in the cooling, forming and other links in the entire production process. In addition, the lower melting temperature reduces the erosion of the refractory materials by the high temperature in the kiln, thereby extending the service life of the kiln and reducing maintenance costs.

- Secondly, the rich alumina and silica components of albite play a key chemical strengthening role in the glass melt. As a network former, alumina can enhance the stability of the glass network structure and improve the hardness and wear resistance of the glass. Silicon dioxide, as the main component of the network skeleton, further strengthens the structural strength of the glass. This chemical reinforcement significantly improves the mechanical strength of glass fiber, allowing it to withstand greater tension and pressure and is less likely to break. At the same time, the chemical corrosion resistance of glass fiber is enhanced, so that it can maintain stable performance in various harsh environments, and broaden the application scope of glass fiber.

- Furthermore, albite has excellent rheology control ability, which is crucial for the molding of glass fibers. The quality of rheological control ability directly affects the fluidity and formability of molten glass. The addition of albite enables the glass melt to maintain ideal fluidity in a high temperature environment, making it easy to draw into uniform glass fibers. This not only ensures the uniformity and fineness of the glass fiber, but also improves production efficiency and reduces the scrap rate.

- Finally, the introduction of albite has a significant impact on the optical properties of glass fibers. The specific components in albite can adjust the refractive index, transmittance and dispersion characteristics of glass, making glass fiber show broader application prospects in optoelectronics, communications, new energy and other fields.

The application of albite as flux in glass fiber production has significant advantages and potential. It can not only improve product performance and market competitiveness, but also inject strong impetus into the continued prosperity of the glass fiber industry. Ankai will continue to provide you with high-quality albite products. If you have any needs, please contact us.