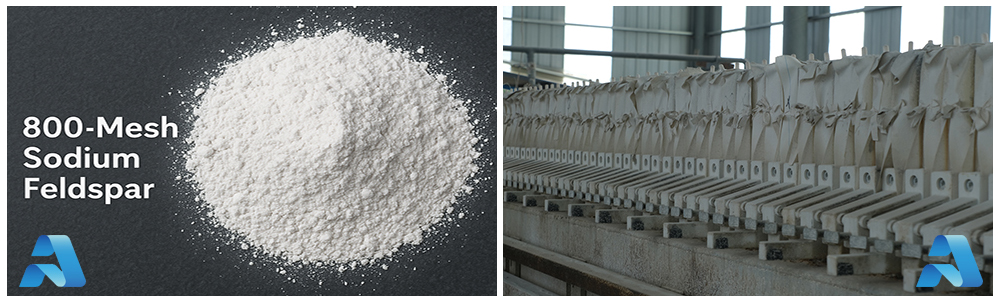

With the continuous advancement of modern industrial technology, sodium feldspar, as an important non-metallic mineral raw material, has become increasingly valuable in many fields. In particular, sodium feldspar powder, which has been finely processed to 800 mesh, has become an indispensable high-quality raw material for industries such as ceramics, glass, and coatings due to its superior physical and chemical properties and higher purity.

Sodium feldspar (Na₂O·Al₂O₃·6SiO₂) is an aluminum silicate mineral rich in sodium, with good chemical stability, high hardness and high temperature resistance. By ultra-fine grinding to 800 mesh (particle size of about 15-20 microns), its specific surface area is significantly increased, enhancing its applicability in various industries.

According to industry data, the purity of 800 mesh sodium feldspar can reach more than 95%, and the Fe₂O₃ content is less than 0.15%, which can significantly improve the product quality in high-end glass and ceramic production. In addition, its Mohs hardness is 6-6.5 and its melting point is about 1100-1200℃, which can effectively reduce the firing temperature and save energy consumption during ceramic sintering and glass melting.

Glass industry: improving transparency and strength

In the glass manufacturing process, sodium feldspar, as a flux, can reduce the melting temperature of silica sand and improve the forming performance of glass. Data show that the light transmittance of float glass with 800 mesh sodium feldspar can be increased by 2%-5%, while improving the mechanical strength of the glass, making it more resistant to impact and thermal shock.

Ceramic industry: improving density and heat resistance

In ceramic production, 800 mesh sodium feldspar can not only improve the plasticity of the body, but also improve the gloss of the glaze. Studies have shown that the use of glazes with a high sodium feldspar content can increase the gloss of the glaze by more than 10%, while reducing the water absorption rate of ceramic products and enhancing thermal shock resistance.

Coatings and paints: enhancing weather resistance and corrosion resistance

800 mesh sodium feldspar as a filler can improve the hiding power, wear resistance and weather resistance of the coating. Experimental data show that when the sodium feldspar filling amount reaches 20%-30%, the UV resistance of the coating can be improved by 15%-20%, extending the life of the coating.

Rubber and plastic: Improve wear resistance and mechanical properties

In rubber and plastic products, 800 mesh sodium feldspar is used as a functional filling material to improve the rigidity and dimensional stability of the products. PVC plastic products with 5%-10% sodium feldspar powder added can increase their impact strength by about 8%-12%, and are widely used in automotive interiors, building materials and other fields.

Welding rod industry: Optimizing fluxing performance

As a flux in welding rod production, sodium feldspar can improve the stability of the welding process and improve the quality of the weld. According to statistics, the welding electrode using high-purity sodium feldspar as a fluxing material can increase its welding deposition rate by about 5% and reduce welding defects.

With the implementation of global green manufacturing and energy-saving and consumption-reduction policies, the application areas of sodium feldspar will be further expanded, especially in the fields of high-end electronic glass, new energy ceramics and advanced composite materials. Industry experts predict that the global ultrafine sodium feldspar market will maintain an average annual growth rate of 6%-8% in the next five years, providing better raw material support for high-end manufacturing.

Overall, 800 mesh sodium feldspar has shown irreplaceable advantages in many industries due to its excellent physical and chemical properties. If you want to know more, please contact Henan Ankai New Materials Co., Ltd.!

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.