In the Soda Feldspar production process, magnetic separation is a crucial link. It plays a key role in improving the purity of the ore and product quality throughout the production process. The following is a professional and detailed description of the magnetic separation link in the Soda Feldspar production process:

Definition and principle of magnetic separation

Magnetic separation is a mineral separation method that uses the magnetic differences between minerals to separate magnetic minerals from non-magnetic minerals in a magnetic field. Since iron impurities in Soda Feldspar are usually magnetic, while Soda Feldspar itself does not have strong magnetism, magnetic separation can effectively separate iron impurities from Soda Feldspar.

The role of magnetic separation in Soda Feldspar production

Iron impurities in Soda Feldspar can seriously affect the quality and performance of the product, such as color changes, lower melting points and reduced mechanical strength.

Magnetic separation uses the action of a magnetic field to adsorb iron impurities on the magnetic poles of the magnetic separation equipment, thereby achieving the removal of iron impurities.

The purity of Soda Feldspar after magnetic separation is significantly improved, providing high-quality raw materials for subsequent processing.

High-purity Soda Feldspar has wider application value in the ceramics, glass and electronics industries.

As an important link in the Soda Feldspar production process, magnetic separation plays a key role in optimizing the entire production process with its high efficiency and stability.

Magnetic separation can ensure the smooth progress of subsequent processing and improve production efficiency.

Selection and use of magnetic separation equipment

Commonly used magnetic separation equipment includes weak magnetic separation equipment and strong magnetic separation equipment.

Weak magnetic separation equipment is mainly used to separate highly magnetic iron minerals, such as magnetite.

Strong magnetic separation equipment is suitable for separating weakly magnetic iron minerals, such as hematite and goethite.

In the Soda Feldspar production process, magnetic separation equipment is usually used in the roughing and concentrating stages.

In the roughing stage, magnetic separation equipment can quickly remove a large amount of iron impurities and improve the grade of the ore.

In the selection stage, magnetic separation equipment further purifies the ore to ensure the quality and performance of the final product.

Regular maintenance and upkeep of magnetic separation equipment is essential to maintain its efficiency and stability.

Magnetic separation equipment should be inspected regularly to ensure that its magnetic field strength, magnetic pole gap and other parameters are in optimal condition.

At the same time, the transmission parts of the magnetic separation equipment should also be lubricated and cleaned to prevent wear and blockage from affecting its normal operation.

Evaluation and optimization of magnetic separation effects

The effect of magnetic separation is usually evaluated by detecting the content of iron impurities in the ore after magnetic separation.

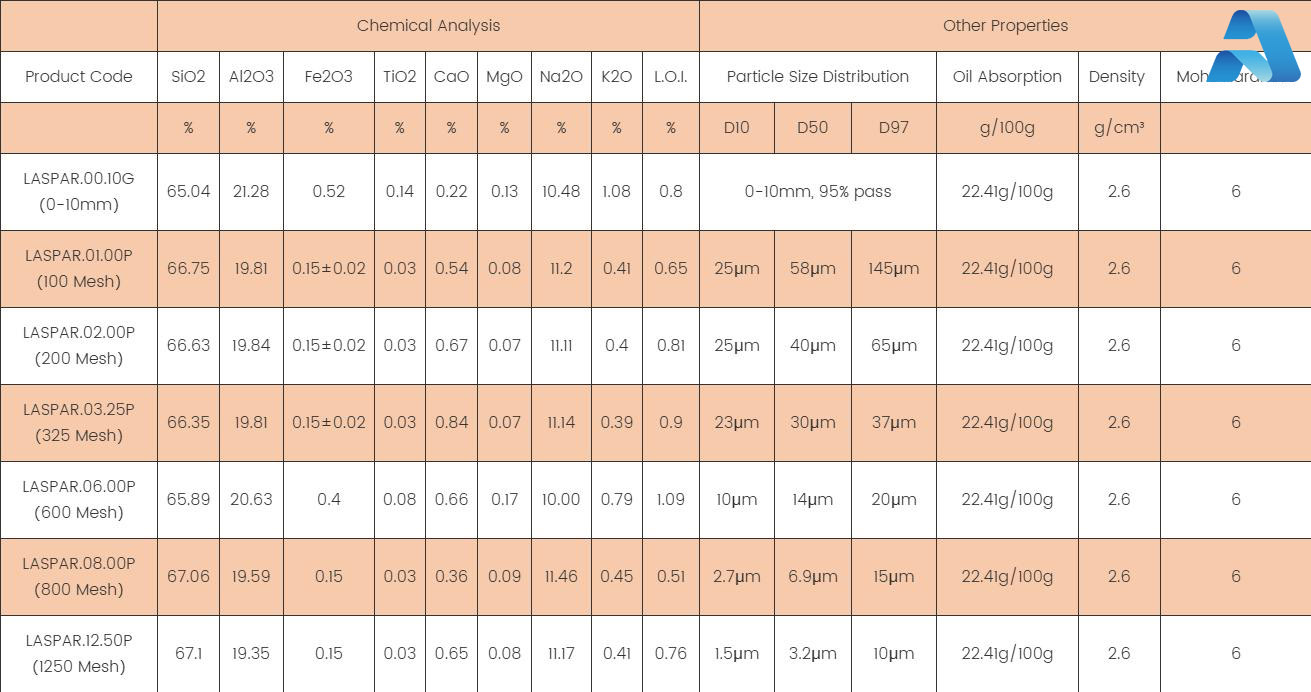

The purity of the ore after magnetic separation can be detected through chemical analysis, physical testing and other methods.

The magnetic separation effect can be optimized by adjusting the magnetic field strength, magnetic pole gap and other parameters of the magnetic separation equipment.

At the same time, the ore can also be pretreated, such as crushing, grinding, etc., to improve the efficiency and quality of magnetic separation.

In summary, magnetic separation plays a vital role in the Soda Feldspar production process. Through reasonable magnetic separation process and equipment selection, iron impurities in Soda Feldspar can be effectively removed, the purity of the ore and product quality can be improved, the production process can be optimized, and high-quality raw materials can be provided for the wide application of Soda Feldspar.

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.