Glass fiber, as a lightweight and high-strength material with excellent performance, is widely used in construction, transportation, electronics, environmental protection and other fields. As one of the key raw materials for glass fiber production, sodium feldspar plays an indispensable role in it. This article aims to understand the application of sodium feldspar in the glass fiber industry and its role in promoting the development of enterprises.

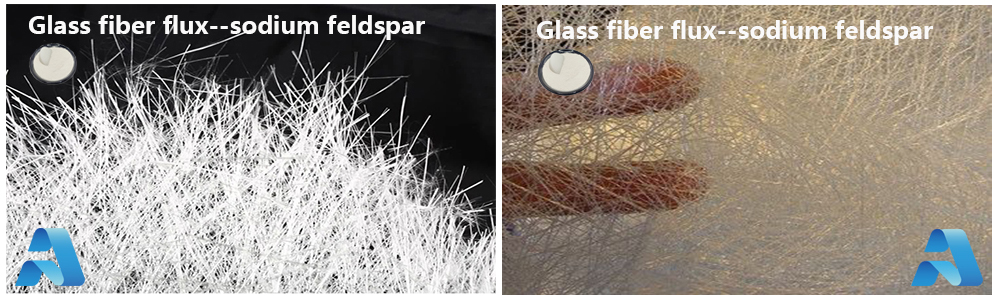

In the production of glass fiber, the main function of flux is to lower the melting point of the raw material mixture, so that the glass can form a uniform liquid at a lower temperature. This is crucial to reducing energy consumption and improving production efficiency. Sodium feldspar has a good fluxing effect because it contains a certain proportion of sodium oxide (Na2O), which can effectively reduce the viscosity of the melt and promote the uniform mixing of various components.

When sodium feldspar is added to the raw material formula for glass fiber production, it can significantly reduce the melting temperature and time. This is because the presence of sodium oxide can destroy the silicon-oxygen network structure, increase the number of free oxygen ions, and thus reduce the viscosity of the glass liquid. This not only helps to quickly form a stable glass liquid phase, but also speeds up the entire production process and reduces energy consumption. Especially in large-scale industrial production, this characteristic is particularly important for reducing costs and increasing output.

Enhance chemical stability: The addition of sodium feldspar helps to improve the chemical stability of glass fiber. By adjusting the composition of the glass liquid, sodium feldspar can improve the resistance of glass fiber to the external environment, including acid and alkali resistance, weathering resistance and other properties. This is of great significance for extending the service life of glass fiber products.

Improve mechanical strength: The aluminum element in sodium feldspar can form a tighter three-dimensional network structure with silicon, thereby enhancing the mechanical strength of glass fiber. This enhancement effect is particularly critical for application scenarios requiring high strength, such as building reinforcement materials, lightweight automotive components, etc.

Optimize thermal stability: The introduction of sodium feldspar can also improve the thermal stability of glass fiber. By adjusting the thermal expansion coefficient of the glass liquid, it can better match the temperature change requirements in actual applications, avoiding product failure problems caused by temperature fluctuations.

With the increasing global environmental awareness, green production has become an important trend in the development of the industry. As a natural mineral, sodium feldspar is relatively easy to control environmental pollution during mining and processing. In addition, using sodium feldspar as a flux can reduce the emission of greenhouse gases such as carbon dioxide by lowering the melting temperature, which is in line with the concept of sustainable development.

Henan Ankai New Materials Co., Ltd., as a leading sodium feldspar supplier in China, not only focuses on product quality and technological innovation, but also actively expands the application of sodium feldspar powder in other fields. In plastic modification, sodium feldspar powder, as an inorganic filler, can enhance the hardness, wear resistance and thermal stability of plastics, while reducing the density and cost of plastics and broadening the application range of plastics. In addition, sodium feldspar powder also shows broad application prospects in the fields of ceramics, glazes, coatings and refractory materials.

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.