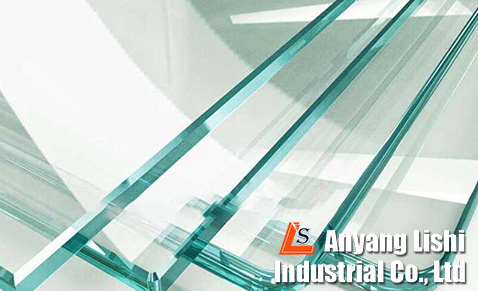

Fiberglass is a special synthetic fiber, it is a material composed of many extremely fine glass fibers. This is a very strong fiber. The versatility of fiberglass makes it a unique industrial textile material. Fiberglass in fabric form offers an excellent combination of properties from high strength to fire resistance.

Glass fibers exhibit useful bulk properties such as stiffness, clarity, resistance to chemical attack, stability, and inertness, as well as desirable fiber properties such as strength, flexibility, and stiffness. Fiberglass is used in the manufacture of structural composites, printed circuit boards, and a variety of special-purpose products. It is used in the manufacture of fire-resistant, waterproof fabrics, high-performance aircraft (gliders), boats, cars, bathrooms, hot tubs, water tanks, roofs, pipes, cladding, castings, surfboards, and exterior door skins.

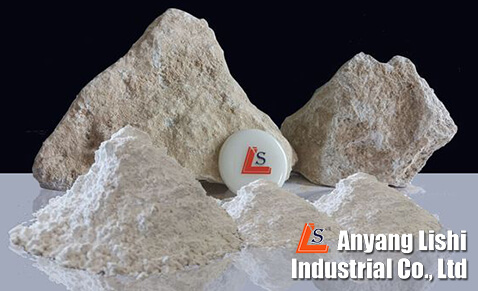

Albite, a form of sodium feldspar, plays a pivotal role in the glass fiber industry. Its unique properties make it a valuable component in the manufacturing process of glass fibers, revolutionizing various sectors from construction to automotive and electronics.

In the realm of glass fiber production, albite serves as a fundamental raw material. Its inclusion in the glass composition significantly influences the characteristics of the final product. When combined with silica, limestone, and other minerals, albite undergoes a fusion process, contributing to the formation of molten glass. This molten mixture, under controlled conditions, is drawn into thin fibers through specialized equipment, eventually solidifying into the glass fibers widely used across industries.

The importance of albite extends beyond mere participation in the fusion process. Its chemical properties alter the viscosity and melting behavior of the glass batch. By lowering the melting temperature and enhancing the fluidity of the molten glass, albite facilitates the manufacturing process, making it more efficient and cost-effective. Moreover, its presence influences the physical and mechanical properties of the resulting glass fibers, impacting aspects such as tensile strength, durability, and thermal stability.

Albite’s ability to fine-tune the properties of glass fibers is a critical factor in achieving the desired performance characteristics in various applications. For instance, in the construction industry, where fiberglass reinforcement is widely employed, the addition of albite contributes to the strength and resilience of the composite materials. Similarly, in the electronics sector, where glass fibers are utilized in circuit boards and insulating materials, albite-modified glass fibers offer improved electrical insulation and mechanical support.

The optical and chemical properties of glass fibers are also influenced by the presence of albite. Its composition affects factors like refractive index and chemical resistance, making the resulting fibers suitable for diverse applications. This versatility has led to the widespread adoption of glass fibers across industries, ranging from aerospace to healthcare.

Albite’s role in the glass fiber industry is multifaceted and indispensable. Its contribution to the manufacturing process, coupled with its ability to modify the properties of glass fibers, makes it an integral component in producing high-performance materials that fuel technological advancements across various sectors. As industries continue to innovate and demand superior materials, albite remains a key ingredient in shaping the future of the glass fiber industry.

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.