100 mesh sodium feldspar powder is a high-quality raw material widely used in ceramic, glass and refractory industries. As a direct sales manufacturer, LSAK feldspar ensures more competitive prices while ensuring stable and reliable quality.

Call Anytime:

+86 15837207537Send E-mail:

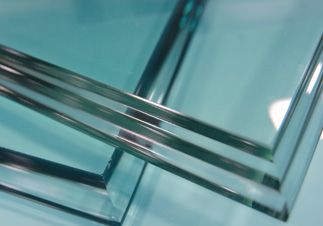

info@lsakminerals.comSodium feldspar (LSAK feldspar) produced by Henan Ankai New Materials Co., Ltd. is a key raw material for the glass industry. Sodium feldspar (Na₂O·Al₂O₃·6SiO₂) provides aluminum oxide (Al₂O₃) and sodium oxide (Na₂O) for glass. Al₂O₃ enhances chemical stability and mechanical strength, and Na₂O acts as a flux to reduce the melting temperature and save energy.

| Al2O3 | 19.81% | Al2O3 is generally 15-18%, ours is 19.81%, high aluminum can burn quickly at low temperatures |

| SiO2 | 66.75% | |

| Fe2O3 | 0.13% | low iron can increase whiteness |

| Na2O | 11.2% | Na2O with a content of more than 10% is high sodium, and sodium improves the gloss and light transmittance of the product |

| CaO | 0.54% | |

| MgO | 0.08 | |

| K2O | 0.41 | |

| TiO | 0.03 | |

| Whiteness | 54.9 | Suitable for ceramic industry |

| Sodium feldspar powder from LSAK Feldspar has the advantages of fast burning at low temperatures, increasing whiteness and gloss | ||

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.