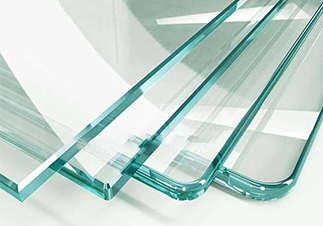

Sodium Feldspar is also called as Soda Feldspar, is a Sodium Aluminosilicate (NaAlSi3O8). As a flux and filler, Sodium feldspar is widely used in ceramics, glass, coatings, plastics, refractory materials, etc.

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.com1000-1300kg per bags.

• High sodium (Na11%)and High aluminum content(Al20%), has nepheline properties and good transparency

• Low Silicon and without free silicon, it's harmless to the body

• Na 11% around, Fast burning at a lower temperature, save cost

• Properties of translucent nepheline

• Good transparency

| Chemical Analysis | Other Properties | ||||||||||||||

| Product Code | SiO2 | Al2O3 | Fe2O3 | TiO2 | CaO | MgO | Na2O | K2O | L.O.I. | Particle Size Distribution | Oil Absorption | Density | Mohs Hardness | ||

| % | % | % | % | % | % | % | % | % | D10 | D50 | D97 | g/100g | g/cm³ | ||

|

LASPAR.00.10G (0-10mm) |

65.04 | 21.28 | 0.52 | 0.14 | 0.22 | 0.13 | 10.48 | 1.08 | 0.8 | 0-10mm, 95% pass | 22.41g/100g | 2.6 | 6 | ||

|

LASPAR.01.00P (100 Mesh) |

66.75 | 19.81 | 0.13 | 0.03 | 0.54 | 0.08 | 11.2 | 0.41 | 0.65 | 25μm | 58μm | 145μm | 22.41g/100g | 2.6 | 6 |

|

LASPAR.02.00P (200 Mesh) |

66.63 | 19.84 | 0.15 | 0.03 | 0.67 | 0.07 | 11.11 | 0.4 | 0.81 | 25μm | 40μm | 65μm | 22.41g/100g | 2.6 | 6 |

|

LASPAR.03.25P (325 Mesh) |

66.35 | 19.81 | 0.15 | 0.03 | 0.84 | 0.07 | 11.14 | 0.39 | 0.9 | 23μm | 30μm | 37μm | 22.41g/100g | 2.6 | 6 |

|

LASPAR.06.00P (600 Mesh) |

65.89 | 20.63 | 0.4 | 0.08 | 0.66 | 0.17 | 10.00 | 0.79 | 1.09 | 10μm | 14μm | 20μm | 22.41g/100g | 2.6 | 6 |

|

LASPAR.08.00P (800 Mesh) |

67.06 | 19.59 | 0.15 | 0.03 | 0.36 | 0.09 | 11.46 | 0.45 | 0.51 | 2.7μm | 6.9μm | 15μm | 22.41g/100g | 2.6 | 6 |

|

LASPAR.12.50P (1250 Mesh) |

67.1 | 19.35 | 0.15 | 0.03 | 0.65 | 0.08 | 11.17 | 0.41 | 0.76 | 1.5μm | 3.2μm | 10μm | 22.41g/100g | 2.6 | 6 |

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.